Coaching Conversations (ICC Commercial Mechanical Inspector)

These are actual coaching conversations from our online ICC Commercial Mechanical course.

Our coaching system is simple and convenient. You can easily ask a question anywhere in the course. There's no need to open your email program or go to another page.

How do we get 350cfm?

The question is: "A fan is installed to bring in outdoor combustion air for a 1,000,000 btu/h boiler. What is the airflow requirement for the fan?"

Answer 1: 175 cfm

Answer 2: 350 cfm

Answer 3: 500 cfm

Answer 4: 700 cfm

The correct answer is: Answer 2.

My answer was: Answer 3.

IFGC 304.9 says "Where all combustion air is provided by a mechanical air supply system, the combustion air shall be supplied from the outdoors at a rate not less than 0.35 cubic feet per minute per 1,000 Btu/h (0.034 m^3/min per kW) of total input rating of all appliances located within the space."

In other words, if you are using a fan to provide combustion air, the fan must provide 0.35 cfm for every 1,000 btu/h of fuel input. Our boiler is 1,000,000 btu/h. So the math is:

0.35 cfm / 1,000 btu/h * 1,000,000 btu/h = 350 cfm.

Feel free to ask any follow up questions if it still doesn't make sense.

Makes sense

Thank you

As per the statement in IFGC 304.10 , I understood that for metal 75% of the free area so 0.75x400=300. Please clarify to make me understand the statement correctly.

The question is: "400 square inches of open area in an opening are required to bring combustion air into a furnace room. If a metal louver is being installed in the opening, what area of metal louver is required?"

Answer 1: 225 square inches

Answer 2: 300 square inches

Answer 3: 400 square inches

Answer 4: 533 square inches

The correct answer is: Answer 4.

My answer was: Answer 2.

Let's make a distinction between the opening size and the net free area. Imagine you are cutting a rectangular hole in a wall to place a louver. If you cut a hole that is 10 inches x 10 inches, the area is 100 square inches. That is the opening size. Now, if you place a louver in the hole, the blades and the frame will block some of the hole. The net free area is the unblocked portion of the hole. For a metal louver, the assumption is that the net free area is 75% of the opening size. In our example, that net free area would be 75 square inches.

Now, in the problem, I've given you the net free area, not the opening size. I'm asking you for what the opening size needs to be. The opening size is always larger than the net free area. (100 is larger than 75). You need to divide by 75%, not multiply, to get the larger value. 400/0.75 = 533.

Got it, thanks for your explanation

Can you explain the answer please?

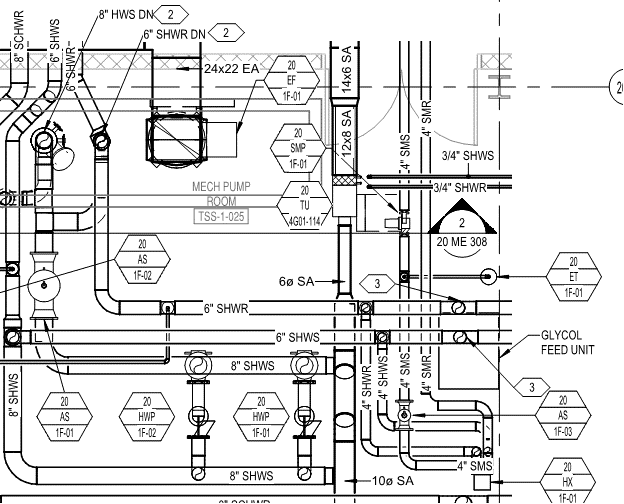

The question is: "Using the drawing above, what is the size of the snowmelt supply and return pipe?"

Answer 1: 4 inches

Answer 2: 6 inches

Answer 3: 8 inches

Answer 4: 10 inches

The correct answer is: Answer 1.

My answer was: Answer 3.

The drawing used in this question comes from a real project where SMS and SMR were not defined on a legend sheet. You have to infer that "snowmelt supply" and "snowmelt return" will be abbreviated somehow, so look for anything that could represent those two systems. SMS and SMR are in the upper right corner of the drawing image, both showing 4" as their size.

How do you know that the answer is related to extra-heavy-duty?

The question is: "A large charcoal grill is placed under a wall-mounted canopy hood that is 10 feet long. What is the total required airflow rate for the hood?"

Answer 1: 4000 CFM

Answer 2: 6000 CFM

Answer 3: 5500 CFM

Answer 4: 7000 CFM

The correct answer is: Answer 3.

My answer was: Answer 1.

"Extra-heavy-duty cooking appliance" is italicized, so you know it has a definition in Chapter 2. The definition is "Extra-heavy-duty cooking appliances are those utilizing open flame combustion of solid fuel at any time." Because charcoal is a solid fuel, it is an extra-heavy-duty cooking appliance.

How do you find this out?

The question is: "For vertical piping, midstory guides are required for all the following except ______."

Answer 1: a. ABS pipe

Answer 2: b. Copper pipe

Answer 3: c. Polypropylene pipe

Answer 4: d. PVC pipe

The correct answer is: Answer 2.

My answer was: Answer 4.

If running short on time, and if you know that PVC, ABS, and Polypropylene are all plastic pipes, you could guess copper pipe, since it is unlike the others, and you'd be right. Or, in Table 305.4, footnote c says "mid-story guide". Footnote c. is referenced for all the plastic pipe and tubing. Plastic is typically more flexible than metal and requires more support.

Thank you for your response!

If we don't remember the answer, how do we remember the section?

The question is: "Where gas is supplied at a pressure higher than _______ serving appliances that operate at a gas pressure of __________ or less, overpressure protection devices are required."

Answer 1: 2 psi, 14 in. w.c.

Answer 2: 1 psi, 14 in. w.c.

Answer 3: 2 psi, 7 in. w.c.

Answer 4: 1 psi, 7 in. w.c.

The simple answer is tabs, index, and table of contents.

Tabs: You are allowed to put sticky tabs on your code book that you use during the test. There can't be any loose papers in your code book, but index tabs can help you find sections quickly.

If you don't have a tab for the question or you choose not to use them, the index and table of contents are a great resource. For example, the table of contents will tell you that Chapter 4 is "GAS PIPING INSTALLATIONS" and Section 416 is "Overpressure Protection Devices". "Overpressure Protection Devices" is also an entry in the index.

I am learning chapter 5 sizing vents for single appliances, on step 2c, how can I find the information for high altitude less input information on the code book?

IFGC 504.2.5 didn't mention anything about this 2% or 4% reduction

and same chapter, step 3c, where does "the vent can only be reduced if vent height is more than 10 ft" come from the code book?

and where can I find that table under step 3C from the code book?

The IFGC does not cover how to derate appliances for altitude. It is often dictated by the manufacturer. Other codes have more description on how to derate appliances for altitude. For example, the Nevada Mechanical Code gives three options: 1. 4% reduction for every 1,000 feet above 2,000. 2. How the AHJ decides. 3. According to manufacturer's instructions.

Usually, 4% is the max and 2% is the minimum, but high altitude kits with combustion air compression can make it so no derate is required. The modules are there to teach you the subject, the code books are not. Examples and information given in the module go outside of the code book to give you context on what the code is saying. You will not find it all in the codes. In those cases, you will not be tested on that information, but knowing it helps your understanding.

3C comes from 504.2.2. The table that 3C mentions is 504.2(1) through 504.2(6). The table I show in the module is just all 6 parts of the table put together in one view.

Can you please show me how we get 20% . Thank you

The question is: "A 4-inch diameter single wall connector is used to connect a Category I appliance to a chimney. How much does the maximum capacity of the vent connector have to be reduced if the connector has three 90-degree elbows and two 45-degree elbows?"

Answer 1: 10 percent

Answer 2: 20 percent

Answer 3: 30 percent

Answer 4: 40 percent

The correct answer is: Answer 2.

My answer was: Answer 1.

Refer to IFGC 504.3.7

Two 90-degree elbows are already accounted for, so we have to reduce the capacity based on one more 90-degree elbow and two 45-degree elbows. According to 504.3.7, the reduction is 10% for 90-degree elbows and 5% for 45-degree elbows. 10% + 5% + 5% = 20%. I hope that helps.

it is mentioned in the question that " flammable vapors" so as per the table 510.8.2 last row is flammable vapors with 6 inch, please clarify about 12 inch as a correct answer.

The question is: "What is the minimum clearance to combustibles for a hazardous exhaust duct of flammable vapors that operates at a maximum temperature of 150º F?"

Answer 1: 1 inch

Answer 2: 6 inches

Answer 3: 12 inches

Answer 4: 16 inches

The correct answer is: Answer 3.

My answer was: Answer 2.

The question tricked you. You fixated on flammable vapors, but the question says the temperature can get up to 150ºF. The second item in the table is 100-600ºF exhaust which requires 12 inch clearance.

ok

I'm having a hard time understanding the combustion air section in the IFCG. How are you calculating the square footage needed for the building size based on the air volume calculations?

To get from square footage to volume, you multiply the ceiling height by the square footage. Volume = Area x height.

To get from volume to square footage (area), you divide the volume by the ceiling height. Area = Volume / height.

That's perfect. Thank you.

I went to section 304.9 in the ifgc book and I still cant figure out how we came up with 175 cfm

The question is: "A fan is installed to bring in outdoor combustion air for a 500,000 btu/h boiler. What is the airflow requirement for the fan?"

Answer 1: 175 cfm

Answer 2: 350 cfm

Answer 3: 500 cfm

Answer 4: 700 cfm

The correct answer is: Answer 1.

IFGC 304.9 says that fan-supplied combustion air needs to be 0.35 cfm per 1,000 btu/h of input. Our boiler is 500,000 btu/h. There are 500 thousand btu/h and we need 0.35 cfm for each one of those 500. In math terms: 500 thousand btu/h x 0.35 cfm / thousand btu/h = 500 x 0.35 cfm = 175 cfm.

Got it! Thank you very much!

This question is not related to the chapter 6 of Duct Systems, so why it has been addressed here? Please clarify.

The question is: "Grease ducts serving Type I kitchen hoods shall be constructed of stainless steel with a minimum thickness of _________ or steel with a minimum thickness of _________."

Answer 1: No. 16 gage, No. 18 gage

Answer 2: No. 18 gage, No. 16 gage

Answer 3: No. 24 gage, No. 22 gage

Answer 4: No. 22 gage, No. 24 gage

The correct answer is: Answer 2.

My answer was: Answer 3.

Our course organization doesn't always match the code chapters. Because the exhaust section about grease ducts is talked about ductwork, we put it with the duct systems module. You'll also see that the test overview from ICC does not match the chapters of the code. We try to match our modules to the test breakdown and not to the code chapters.